Biodegradability

PLA and PBAT are both biodegradable polyesters, while corn starch is a natural renewable resource with good biocompatibility. Therefore, this composite material can be decomposed by microorganisms in the natural environment, which helps to reduce environmental pollution.

Environmental protection

This material is derived from renewable resources, such as corn starch, with low carbon emissions and environmental impact. In addition, its biodegradability also helps to reduce the long-term impact of plastic waste on the environment.

Mechanical properties

Both PLA and PBAT have certain mechanical strength, and the addition of corn starch may affect their mechanical properties. The specific mechanical properties depend on the ratio of these components and the processing technology.

Processing performance

Both PLA and PBAT have good processing performance and can be thermoplastic processed on plastic processing equipment. The addition of corn starch may affect its processing performance, but it may also be improved by optimizing the formulation and processing technology.

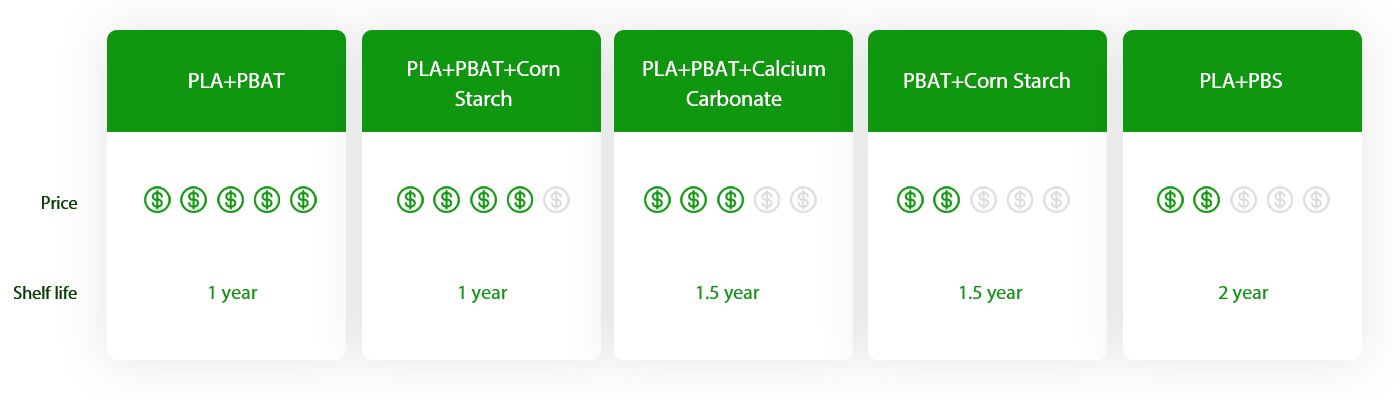

Cost

The cost of this material may be affected by factors such as raw material prices, production processes and market demand. Corn starch, as a relatively cheap raw material, may help reduce the cost of this material.