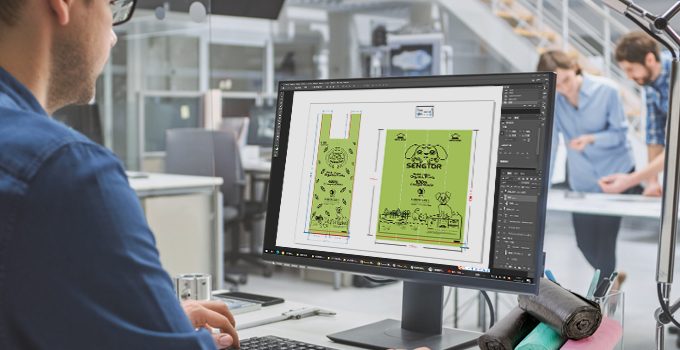

Design team

Professional R&D team can meet customers' customization needs and provide customers with a variety of design styles

Professional R&D team can meet customers' customization needs and provide customers with a variety of design styles

Professional raw material research and development team to solve raw material problems in the industry and provide customized raw material services

Our company has large production workshops, advanced manufacturing equipment, and a professional customization service team. At present, we have set up production bases in Dongguan and Huizhou, China, with an area of more than45,000square meters and a monthly output of more than6 millionpieces.

The quality of the products we manufacture is critical to ensuring your safety, product reliability, and business success. We create effective and consistent quality control processes to avoid product defects and recalls, thereby gaining our customers’ trust in our products and brand.

Appearance inspection:Check whether it is milky white or light yellow, and whether the shape is uniform.

Printing inspection:Compare the masterbatch and check whether there are any indentations on the surface

Packaging inspection:Compare the color and size of the packaging material, measure and check the weight and strength

Extrusion test:Check weight, color pattern, adhesion according to order requirements.

Appearance test:Ensure that there are no straight lines, no streamlines when tearing, and crystal points on the bag

Tensile test:Use electronic tensile machine to test tensile strength and elongation

Tear resistance:Use Elemendorff tear tester to test force

Dart impact force:Use falling dart impact tester to test force

Product specifications:confirm whether they meet the order requirements, such as size, color, printing content, etc.

Product packaging method and contents:use Elemendorff tear tester to test the force

Dart impact force:check whether they meet your order requirements, including their packaging appearance, weight and thickness, etc.

Product performance:check its performance through water quality testing

Shipment confirmation:confirm the batch number of the order, confirm the winding quantity and the shipment quantity, confirm the printing and specifications according to the order

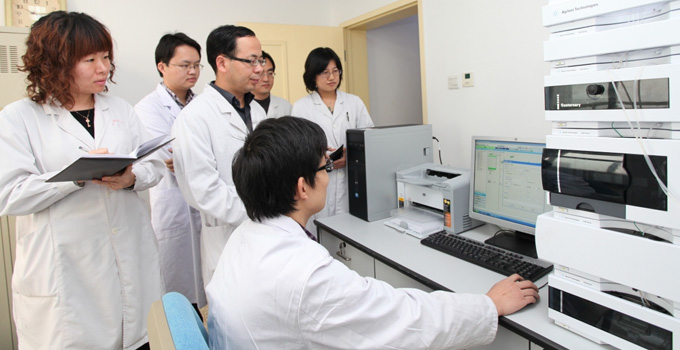

Apply statistical process control (SPC) to monitor and control the manufacturing process, and collect data at various stages of the manufacturing process and analyze it to identify any changes from the set quality standards.

Perform visual and functional inspections and conduct reliable tests to ensure quality.

Establish your own testing center with a professional team to control the standards of each inspection process.

Green energy from renewable energy sources such as wind, solar, and hydro has various benefits. It reduces carbon emissions, mitigates climate change, promotes energy independence, and promotes sustainable development by minimizing the impact on the environment. In addition, the use of green energy supports the innovation of clean energy technology.

With the increasing prominence of structural energy shortages, climate change, environmental pollution and other issues, major economies around the world are actively promoting clean energy transformation.

In order to reduce white pollution and achieve zero waste emissions, Tuosheng Biomaterials actively applies green power facilities like wind power generation, VOC systems, and solar power generation to ensure the normal operation of the entire plant and truly achieve zero emissions.

Compared with traditional fossil energy, green electricity has three major advantages. The first is sustainability. Renewable energy is continuously provided by natural cycles and can be used sustainably. The second is high popularity. Most countries and regions in the world can develop renewable energy, regardless of geographical location and climatic conditions. Third, it is environmentally friendly. Renewable energy generation has low or zero carbon emissions. It has little impact on the environment throughout its life cycle and has a significant impact on reducing pollution and carbon emissions.

We are experts in compostable and degradable materials and can quickly provide you with a one-stop solution for your products. Contact us for help with:

We are a professional environmentally friendly bag manufacturer that quickly helps you achieve your sustainable vision.

Quick Quote